How Steam Locomotives Really Work

Everybody who’s had kids knows that they love trains. I’ve visited the Colorado Railroad Museum and the Forney Transportation Museum several times because of kids. Both museums have a variety of steam locomotives. The Forney has a partially restored Union Pacific Big Boy.

I ended up wanting to know how locomotives worked, and why they look the way they do. Unfortunately, the emphasis at museums is always on how cool steam locomotives are, or the “gee whiz” factor. None of the museum gift shop books seemed to have this sort of content, tending more towards the stamp collecting aspects (4-8-8-4!).

My lovely wife gave me a book, How Steam Locomotives Really Work by P. W. B. Semmens and A. J. Goldfinch as a present.

This very British book (one of the authors has 2 middle names) purports to tell what the official British Rail training manuals did not write down. It might do a good job of that, but it’s also very much more.

You learn a little of the recent history of England through the mergers of the weird little local railways.

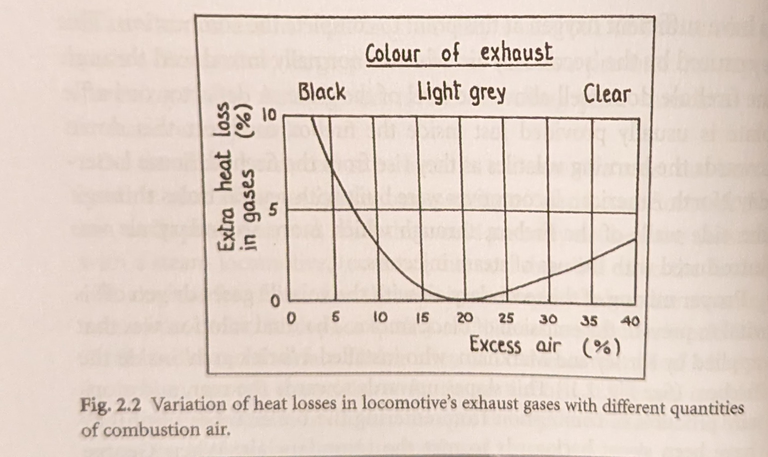

You learn a little about combustion and thermal efficiency through anecdotes, observations about boilers and charts like this:

Apparently they ran steam locomotives a little lean.

Did you know that steam engines constitute an “open” system, where the steam is vented to the atmosphere after being expanded (possibly twice)? Further, the venting is done through the smoke stack, which causes the exhaust to “chuff” and increases the flow of air through the bed of burning coal.

The book spends a very large amount of text on “valve gear”, the mechanical linkages that let steam in to, and out of the cylinders. In these modern times of fuel injectors and electronically-controlled internal combustion engines, we forget that completely mechanical control is possible, and that before, say, 1970, it was the only way to do things. Valve gear design was of immense importance to locomotive function and efficiency. It does make for a boring book chapter, though.

There is a lot to be learned from How Steam Locomotives Really Work. I learned that the driving wheels of a locomotive have “tyres”, which are large steel rings that get shrunk onto the wheels. I learned that in the earlier days of rail, part of a “driver’s” job was to pull the wicks out of the various lubricating reservoirs at the end of the day. If the wicks weren’t pulled out, they’d drip oil all over the place.

I learned that length of trip is limited by water. I had always imagined that stopping to take on fuel happened more often than getting a refill of water, but it’s the other way around. I also learned that the quality of water matters - hard water causes more scale to build up in the boiler. I learned that scale isn’t the only cleaning problem that steam locomotives had. There’s also sludge that precipitates out at the bottom of the boiler. Additionally, coal produces 3 different kinds of combustion byproducts (klinker, ash and char), that have to be periodically cleared. Steam-powered lubrication systems made giant messes. The implication is that running a steam locomotive is deeply filthy, although the book never states this.

Steam engines could have a working lifetime of 50 years, but required lots of maintenance.

The pistons both pushed and pulled.

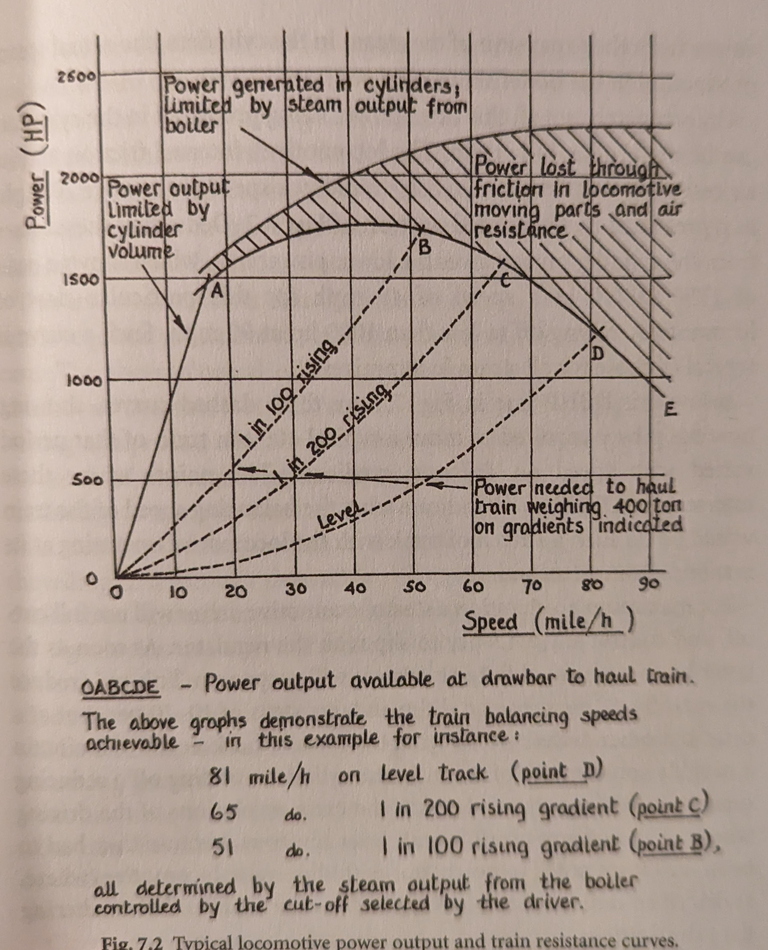

The technical details culminate in a few graphs like this:

Which is exactly the sort of thing I’d been looking for all along.

There’s even a chapter on design of steam locomotives. Like all systems done before 1980, there was some calculation, for the easy stuff, like piston diameter and stroke, and then a whole lot of “intuitive” engineering based on first principles and empirical facts from testing previous locomotives. The first few engines off the assembly line underwent extensive testing. Feedback from the testing went into modifications for the rest of the manufacturing run.

This is a great book if you’re at all curious about steam locomotives, or you’re interested in how complex systems are developed.